E&T Intelligence

Driving Industrial Innovation with E&T's Mobile Manipulation Solutions.

Business Case

Fully autonomous driving and automatic operation of steel slag transport vehicles

We have successfully deployed five specialized heavy-duty vehicles, which have collectively accumulated over 65,00 hours of safe and reliable operation. The technical specifications of the vehicles are as follows:

1. Control Mode: Supports both Self-Driving and Tele-operation.

2. Dimensions: 17 meters in length, 5 meters in width, 3.5 meters in height.

3. Self-Weight: 30 tons.

4. Payload Capacity: 70 tons.

5. Actuation: Internal Combustion Engine (ICE).

6. Navigation: Integration of RTK and visual tracking technologies.

7. Remote Cabin for Tele-operation: Customized by our team

Our team is ready to deliver solutions tailored for both fully autonomous and remote driving capabilities, contingent upon access to the vehicle's wire control protocol. We accommodate various vehicle types, including electric, hybrid, and ICE engines. We can also customize the vehicle design and manipulation mechanisms to meet your needs.

Remote operation of heavy Forklift

Successfully deployed remote operation system at a heavy forklift with a load of 18t in Shanghai.

Remote operation of Copper smelting charging truck

Deploying remote operation system at Copper smelting charging truck.

Intelligent monitor & inspection robot system for a substation

Using intelligent inspection robots instead of manual inspections in substations reduces personnel investment and ensures effective execution of inspections.

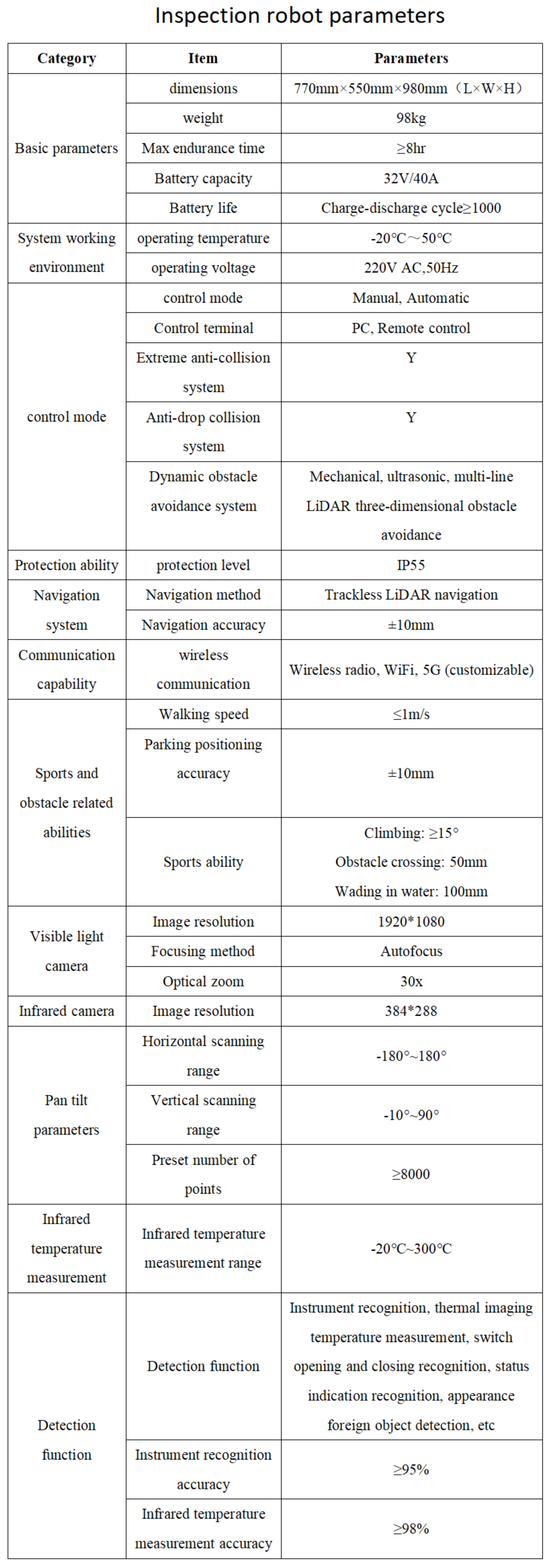

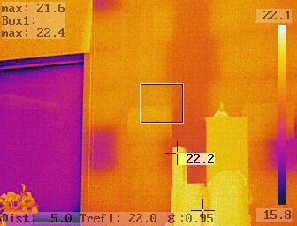

Through intelligent robot inspection, the application of functions such as robot visual inspection, infrared temperature measurement, remote control, intelligent analysis, defect management, knife and switch status discrimination, running and dripping detection, micro meteorological data collection and analysis, and autonomous charging can be achieved, assisting inspection personnel in carrying out routine inspections and other work.

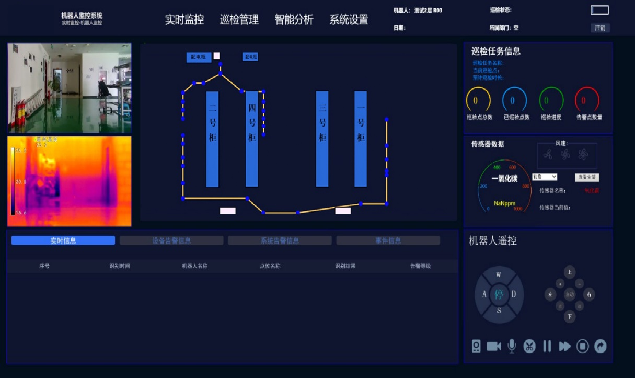

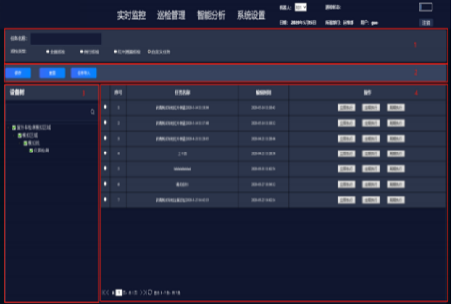

We have built an intelligent inspection robot system for the substation, which consists of an inspection robot body, a backend monitoring system, and a remote centralized management system.

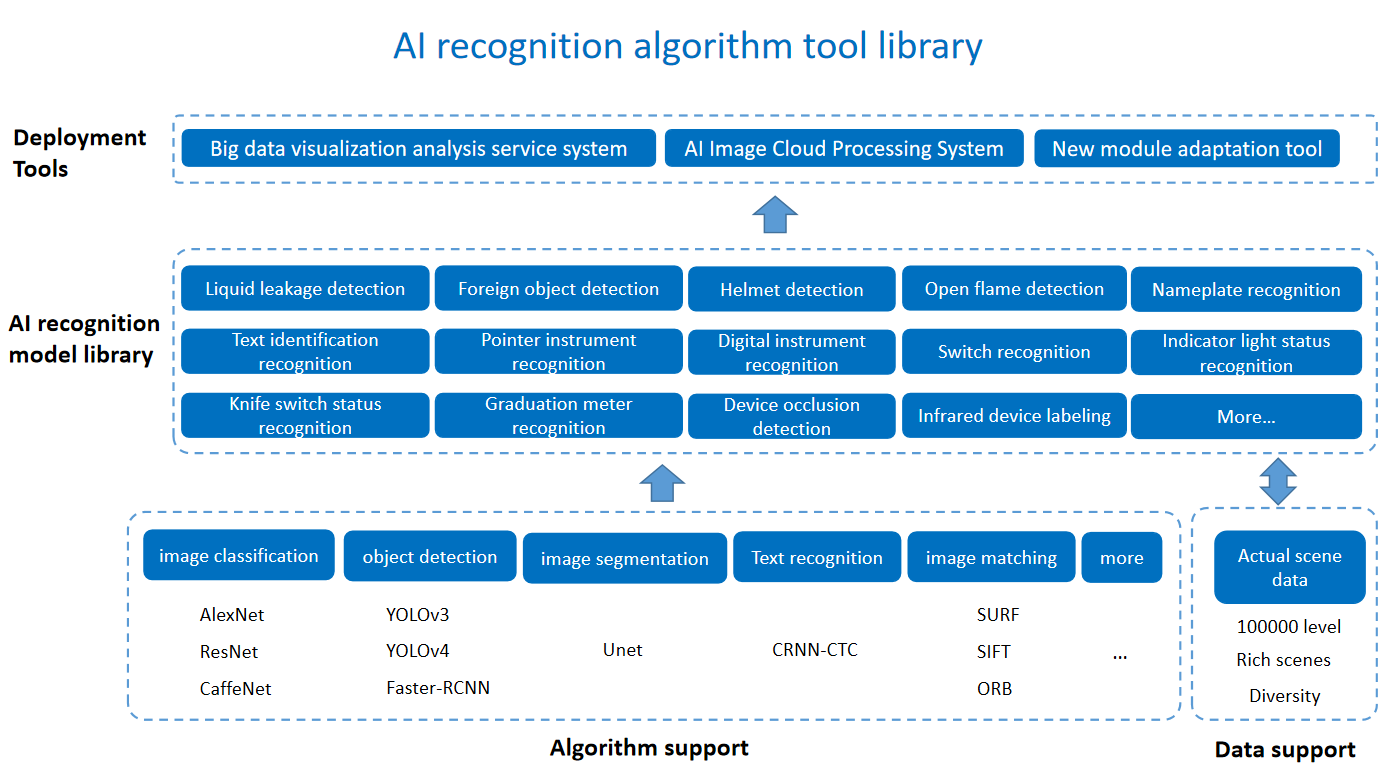

This recognition system adopts distributed neural network image algorithms and extensively introduces AI deep learning methods to establish a high-precision AI recognition algorithm library and a database for demonstration projects in power, energy, industrial production, etc. It can achieve multiple detection functions such as character, pointer, status display, switch, scale, etc. The indoor comprehensive recognition rate can reach over 95%, and the outdoor comprehensive recognition rate can reach 75% to 80%.

Customized remote centralized management system